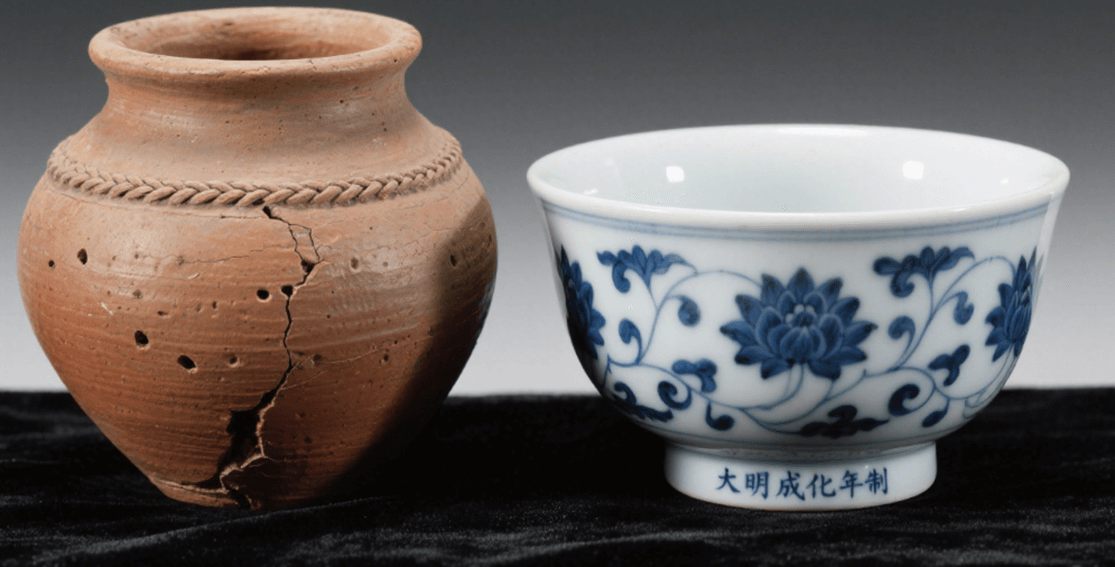

The Difference between Terracotta Clay Pots and Porcelain

In daily life ,terracotta clay pots and porcelain, as two classic types of containers, have always occupied important positions. Although both originate from clay, they show distinct contrasts in function and value due to differences in raw material selection, processing techniques, and performance characteristics. For consumers, understanding the difference between terracotta clay pots and porcelain helps in choosing more suitable products.

Differences in Process Flow

The manufacturing process of Terracotta Clay Pots

Clay pottery uses natural clay as the main raw material, without complex purification, retaining rich minerals and impurities (such as iron oxide) in the clay. It is fired at a relatively low temperature, usually between 800℃-1000℃. The is not fully caking, with a loose structure and tiny pores, presenting a rough and simple texture.

Select natural clay that has not undergone in-depth processing. worker add fine sand to enhance the strength, which is one of the reasons why terracotta clay pots have a tough texture.

Fill the well-kneaded clay into the prefabricated molds (such as the inner and outer molds of a clay pot), and through pressing, rolling and other methods, make the clay adhere to the inner wall of the mold to form structures such as the pot body, pot mouth and pot bottom.

After natural air-drying, workers fire it in a clay kiln or simple kiln at a low temperature. Due to the low temperature, the green body is not fully caking, forming a loose and porous structure.

The manufacturing process of Porcelain

People make porcelain objects using high-purity kaolin (porcelain clay) as the main raw material, mixed with auxiliary materials such as quartz and feldspar, through processes like batching, shaping, glazing, and high-temperature firing (usually above 1200℃-1400℃). Its core characteristics are: after high-temperature firing, the green body becomes dense and hard, with almost no water absorption; the surface has a high-temperature glaze that melts to form a smooth, glass-like layer, which serves both decorative and sealing purposes.This characteristic distinguishes it essentially from terracotta clay pots .

The core steps of making porcelain:

Raw material purification:

Kaolin needs to be repeatedly washed to remove impurities, ensuring pure composition, laying the foundation for the density of the . This is the core difference between ceramic clay and ordinary clay.

Shaping:

worker can shape it through throwing, trimming, and mold printing.. Adopt different shaping methods according to the shape requirements of the porcelain. Common methods include wheel-throwing, mold printing, and slip casting.

High-temperature firing:

Fired at high temperatures., the glaze and undergo chemical reactions to form an integrated glaze. Slight differences in temperature can lead to significant changes in color and texture, so “temperature control” is the key to porcelain firing, which also makes the yield rate of large ceramic pots much lower than that of Clay pottery.

The Application Scenarios of Terracotta Clay Pots and Porcelain Are Different.

Differences in materials and processes directly determine the performance of terracotta clay pots and porcelain, which in turn affect their applicable scenarios.

Clay pottery has the advantages of micro-permeability and water absorption. Its loose structure allows slow air exchange between the inside and outside of the container. However, if you use terracotta clay pots to hold liquids, they need to soak the pots to remove impurities; otherwise, the pots may leak due to water absorption.

Porcelain is known for its density and stability. After being fired at high temperatures, porcelain forms a dense body and glaze, which combine to create a sealed structure. It hardly absorbs water or leaks, has very stable chemical properties, and can resist acid and alkali corrosion. Therefore, porcelain is more suitable for directly holding food and drinks.

Understanding the difference between the two can make your choice more suitable for your needs.